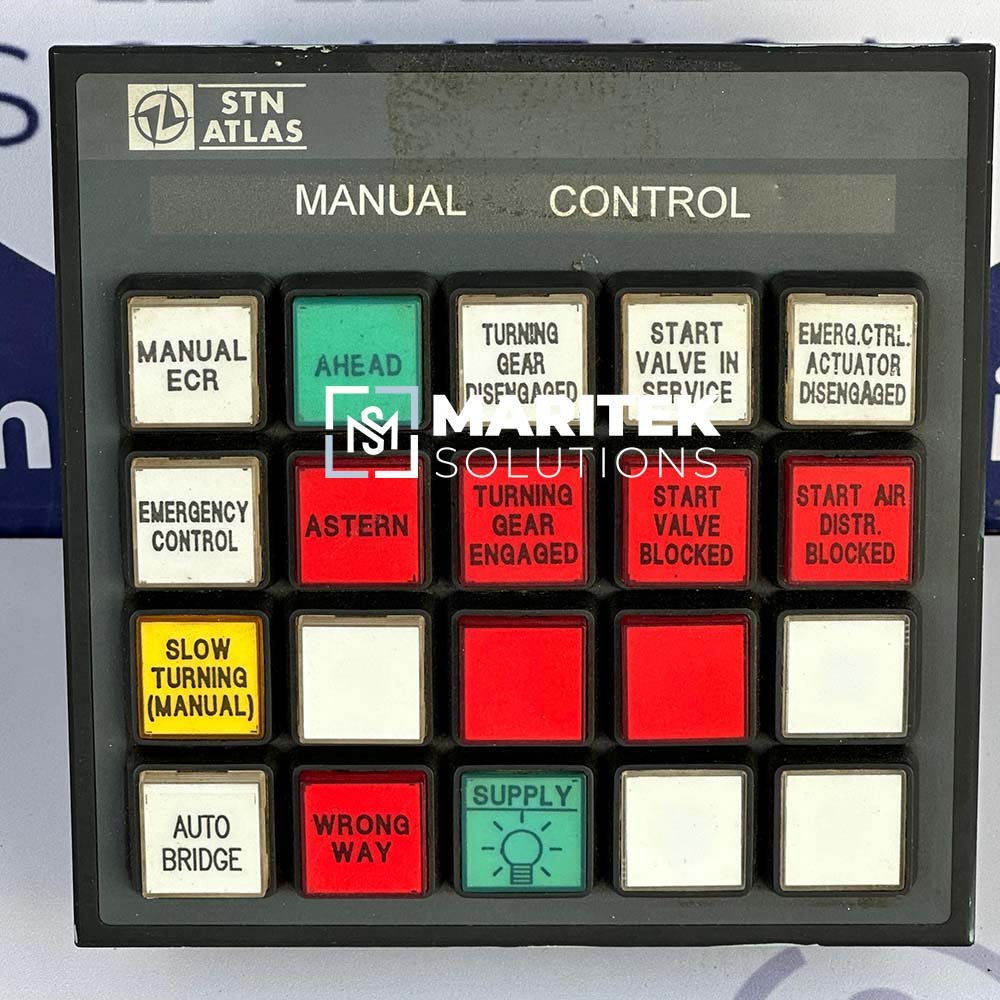

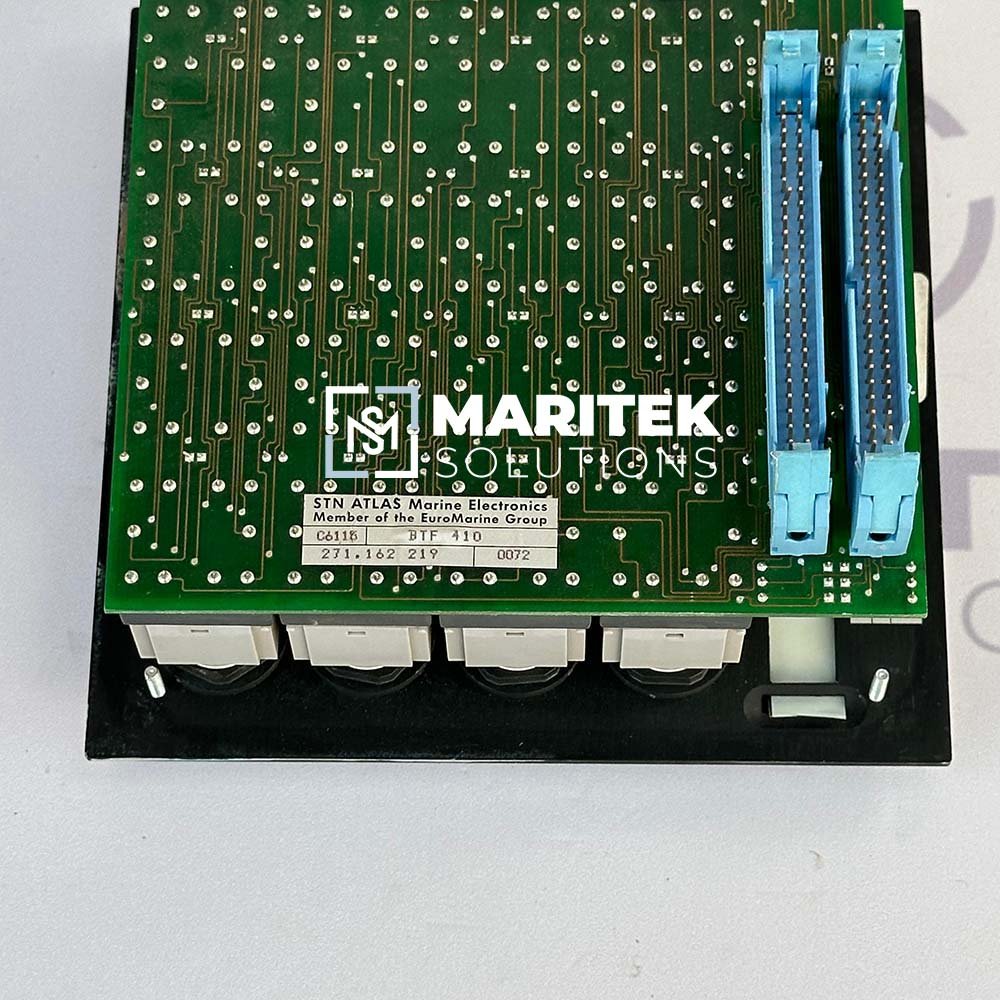

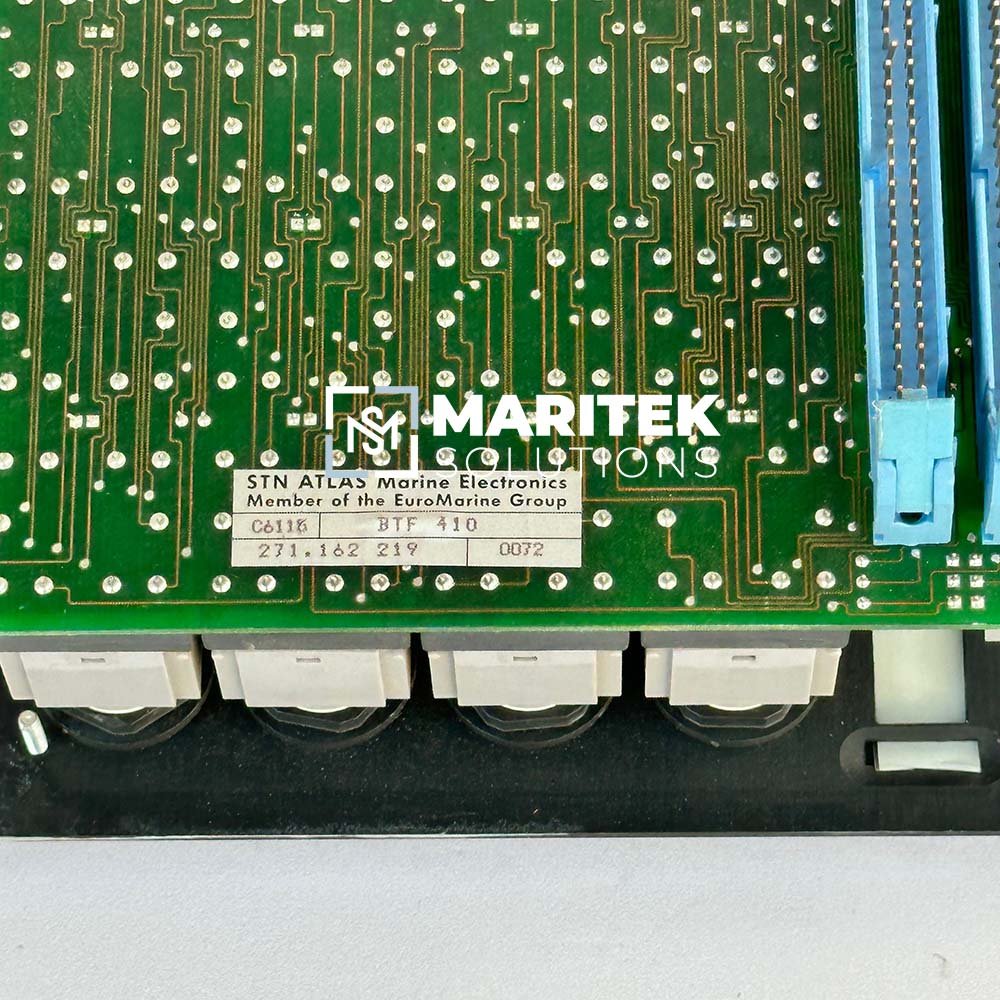

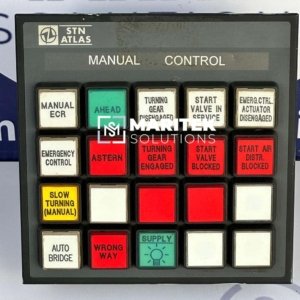

- Maker: STN Atlas Marine Electronics

- Model: C6115 BTF 410

- Description: Module

- Condition: Used service -(7 Days Warranty)

Maritek Solutions can supply new and refurbished spare parts of STN Atlas Marine Electronics.

To receive a quote for STN Atlas Marine Electronics C6115 BTF 410 Module, Kindly email us at info@mariteksolutions.com.